A former manager gifted me a Heath bud vase several years ago. It looks fantastic with a yellow spider mum in it and made me curious about the brand. The HC design studios and showroom are in San Francisco and the dinnerware factory is in Sausalito. Both offer tours. I chose the factory tour.

The tour proceeded in the order of the manufacturing process steps that HC uses to create artisanal product over and over again. According to our tour guide, the founder, Edith Heath, designed the building in a donut shape. Each step of manufacturing is arranged around the donut so that the beginning (a receipt of raw materials) and the end (product on the showroom floor) meet.

Clay Making

The first step in the process is to make clay. The tour guide, Bri, told us that Edith was not satisfied with the clay available on the market so she design a special formulation that was more durable. The ingredients come in, 600 lbs at a time, get dumped into the clay mixer aka a “blunger”, the wood barrel in the photo, to be mixed with water, etc.

After the mixture is the right consistency, it goes over to these machines to have excess water squeezed out of it.

Molding

The clay at this point is a slip the consistency of heavy cream. The slip is poured into molds. Below you can see a cutaway of the mold and the object that it makes. Molds are critical to making the same shape time after time.

After the outer edge of the slip becomes hard in the mold the remaining liquid clay inside is poured out leaving a shape behind.

In the photo above, Bri is surrounded by molds. These molds are good for 60 to 80 pours. Black marks on the mold show how many times a mold has been used.

Trimming

When working with molds, it is common for a lip to form at the top and bottom of the joint where the two halves of the mold meet.

This lip is removed by careful sanding (note the lighted magnifying lamp in the photo below) to avoid any damage to the final piece.

Glazing

Glazing adds dimension, color, and texture. Before firing, a glaze doesn’t look like much necessarily.

Glaze is applied to one piece at a time either by pouring or spraying in a booth.

Heath Ceramics keeps the gram weight of the glaze consistent from one dinner plate to the next to achieve the same dimension, color, and texture. Each piece is weighed before and after the application of glaze to make sure the same amount is applied.

Firing

Each piece passes through one of six kilns to be “fired”. These things are huge, almost room-sized! Bri demonstrates how the operator checks on the pieces inside.

During the firing process, the kilns reach high temperatures ranging from 1800°F to 2200°F (982°C to 1204°C). The clay particles fuse together, creating a solid and sturdy structure and the glaze undergoes chemical changes resulting in the finish and colors that Heath Ceramics is known for.

After firing, the pieces cool slowly inside the kilns to prevent any cracking caused by rapid temperature changes. The yield from a typical kiln run is around 80%. After a final quality inspection, the pieces go to inventory, the showroom, or to customers.

Metrics

Metrics are important for measuring the efficiency and effectiveness of your manufacturing operation especially when you are working to produce artisanal products at scale.

According to Bri, Heath Ceramics produces approximately 9,000 pieces of ceramics per week using these processes. That’s way more quality product than a lone potter can crank out by hand.

The throughput for Forming, Trimming, Glazing, Pieces Fired, and Kilns Fired processes appear to be tracked on a weekly basis. The firing process has the least throughput according to the board below. We toured in June and this board had weekly data from May but no updates for the last 2 weeks in May so it may not be used anymore.

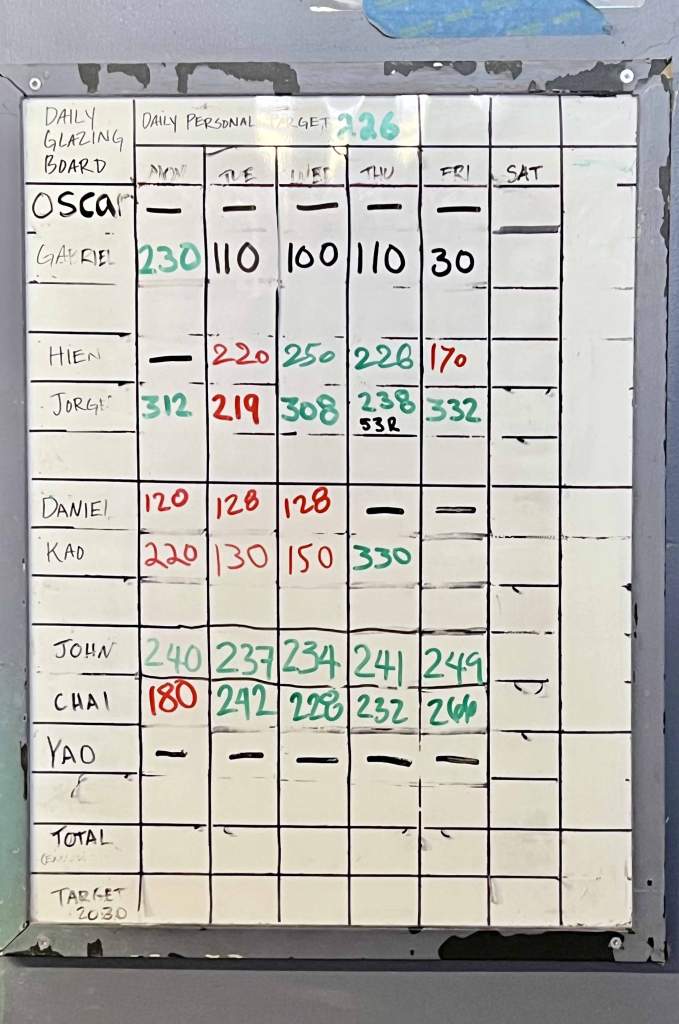

Each area had daily metrics posted as well. We toured on a Saturday and this board had metrics for Monday through Friday, so it could still be in use.

I noticed a metrics manifesto of sorts posted.

History

Edith Heath died in 2005 at the age of 94. Heath Ceramics was purchased by Robin Petravic and Catherine Bailey in 2003. Heath Ceramics is still going strong 20 years after the purchase and 75 years after Edith started it. Wow! I can’t wait to do some reading to discover more.

I did buy a second bud vase while I was there in a wonderful robins egg blue. My first homegrown oriental lilies look fantastic in it!

To Go Yourself

If you are interested in a tour, they are $15/person and you get 10% off your purchase on that day. Register through the Heath Ceramics Factory Tour page.

Enjoy!